Lub lim tiam dhau los, peb tau qhia txog cov txheej txheem winding ntawm cov zaj duab xis capacitors, thiab lub lim tiam no kuv xav tham txog cov thev naus laus zis tseem ceeb ntawm cov zaj duab xis capacitors.

1. Kev siv tshuab tswj kev nruj tas mus li

Vim yog qhov xav tau ntawm kev ua haujlwm zoo, winding feem ntau yog nyob rau ntawm qhov siab siab dua feem ntau hauv ob peb microns. Thiab yuav ua li cas kom ntseeg tau tias qhov nro tas li ntawm cov khoom siv zaj duab xis hauv cov txheej txheem winding ceev ceev yog qhov tseem ceeb tshwj xeeb. Hauv cov txheej txheem tsim peb tsis yog tsuas yog yuav tsum xav txog qhov tseeb ntawm cov qauv kho tshuab, tab sis kuj muaj lub kaw lus tswj kev nruj zoo meej.

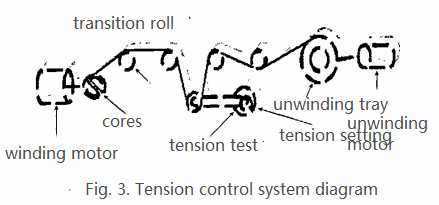

Feem ntau, lub kaw lus tswj hwm muaj ntau ntu: lub tshuab kho qhov nruj, lub ntsuas qhov nruj, lub cev muaj zog kho qhov nruj, lub tshuab hloov pauv, thiab lwm yam. Daim duab qhia txog lub kaw lus tswj hwm qhov nruj tau qhia nyob rau hauv daim duab 3.

Cov capacitors zaj duab xis xav tau qee qib ntawm kev tawv tom qab winding, thiab txoj kev winding thaum ntxov yog siv lub caij nplooj ntoos hlav ua damping los tswj qhov kev nruj ntawm winding. Txoj kev no yuav ua rau muaj kev nruj tsis sib xws thaum lub cev muaj zog winding nrawm, qeeb thiab nres thaum lub sijhawm winding, uas yuav ua rau lub capacitor yooj yim puas tsuaj lossis deformed, thiab qhov poob ntawm lub capacitor kuj loj. Hauv cov txheej txheem winding, qee qhov kev nruj yuav tsum tau tswj hwm, thiab cov mis yog raws li nram no.

F=K×B×H

Hauv daim ntawv qhia no:F-Tesion

K-Cov coefficient ntawm Tesion

B-Zaj duab xis dav (hli)

H-Zaj duab xis tuab (μm)

Piv txwv li, qhov nro ntawm zaj duab xis dav = 9 hli thiab zaj duab xis tuab = 4.8μm. Nws qhov nro yog: 1.2 × 9 × 4.8 = 0.5 (N)

Los ntawm kab zauv (1), qhov ntau ntawm qhov nro tuaj yeem tau los ntawm. Lub caij nplooj ntoos hlav eddy nrog qhov zoo linearity raug xaiv ua qhov chaw teeb tsa nro, thaum lub potentiometer induction magnetic tsis sib cuag siv ua qhov kev ntsuas nro kom tswj tau qhov tso zis torque thiab kev taw qhia ntawm lub cev muaj zog DC servo thaum lub cev muaj zog winding, yog li qhov nro yog qhov ruaj khov thoob plaws hauv cov txheej txheem winding.

2. Kev siv tshuab tswj kev sib txhuam

Lub peev xwm ntawm cov capacitor cores muaj feem cuam tshuam nrog tus lej ntawm cov winding, yog li qhov kev tswj hwm qhov tseeb ntawm cov capacitor cores dhau los ua ib qho thev naus laus zis tseem ceeb. Kev winding ntawm capacitor core feem ntau yog ua tiav ntawm qhov ceev ceev. Txij li thaum tus lej ntawm cov winding tig ncaj qha cuam tshuam rau tus nqi muaj peev xwm, kev tswj hwm ntawm tus lej ntawm cov winding tig thiab suav xav tau qhov tseeb siab, uas feem ntau ua tiav los ntawm kev siv lub module suav ceev ceev lossis lub sensor nrog qhov tseeb pom tseeb. Tsis tas li ntawd, vim yog qhov yuav tsum tau ua kom cov khoom siv nruj me ntsis hloov pauv thaum lub sijhawm winding (txwv tsis pub cov khoom siv yuav tsis txav, cuam tshuam rau qhov tseeb ntawm lub peev xwm), lub winding yuav tsum siv cov thev naus laus zis tswj hwm zoo.

Kev tswj qhov ceev sib cais thiab kev ua kom nrawm / qeeb thiab kev ua tiav qhov ceev sib txawv yog ib qho ntawm cov txheej txheem zoo tshaj plaws: kev sib txawv ntawm qhov ceev winding yog siv rau lub sijhawm sib txawv winding; thaum lub sijhawm sib txawv ceev, kev ua kom nrawm thiab qeeb yog siv nrog cov kab sib txawv ceev kom tshem tawm kev jitter, thiab lwm yam.

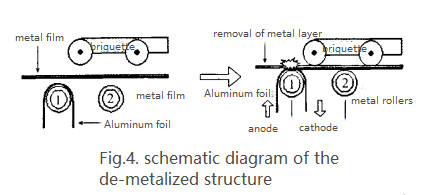

3. Kev Siv Tshuab Demetallization

Ntau txheej ntawm cov khoom siv tau qhwv rau saum ib leeg thiab xav tau kev kho cua sov ntawm sab nraud thiab qhov sib txuas. Tsis tas yuav nce cov khoom siv yas zaj duab xis, cov zaj duab xis hlau uas twb muaj lawm siv thiab nws cov zaj duab xis hlau siv thiab nws cov hlau plating raug tshem tawm los ntawm cov txheej txheem de-metalization kom tau txais cov zaj duab xis yas ua ntej lub foob sab nraud.

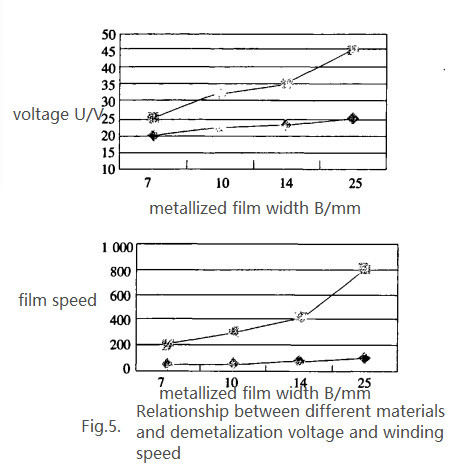

Cov thev naus laus zis no tuaj yeem txuag cov nqi khoom siv thiab tib lub sijhawm txo qhov txoj kab uas hla sab nraud ntawm lub capacitor core (yog tias muaj peev xwm sib npaug ntawm lub core). Ntxiv rau, los ntawm kev siv cov thev naus laus zis demetalization, cov hlau txheej ntawm ib txheej (lossis ob txheej) ntawm cov yeeb yaj kiab hlau tuaj yeem raug tshem tawm ua ntej ntawm lub core interface, yog li zam kev tshwm sim ntawm lub voj voog luv luv tawg, uas tuaj yeem txhim kho cov txiaj ntsig ntawm cov coiled cores. Los ntawm Daim Duab 5, nws tuaj yeem xaus lus tias kom ua tiav tib qho kev tshem tawm. Lub zog tshem tawm yog tsim los kom hloov kho tau los ntawm 0V txog 35V. Qhov ceev yuav tsum tau txo kom txog li ntawm 200r / min thiab 800 r / min rau demetalization tom qab winding ceev ceev. Lub zog sib txawv thiab qhov ceev tuaj yeem teeb tsa rau cov khoom sib txawv.

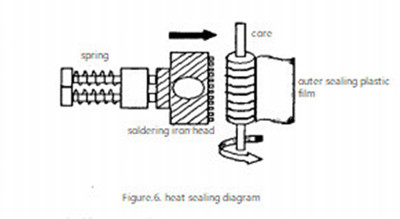

4. Kev siv tshuab kaw cua sov

Kev kaw cua sov yog ib qho ntawm cov thev naus laus zis tseem ceeb uas cuam tshuam rau qhov kev tsim nyog ntawm cov qhov txhab capacitor cores. Kev kaw cua sov yog siv cov hlau kub siab los crimp thiab khi cov yas zaj duab xis ntawm qhov sib txuas ntawm cov capacitor coiled core raws li pom hauv Daim Duab 6. Yog li ntawd lub core yuav tsis raug dov xoob, nws yuav tsum tau khi kom ruaj khov thiab lub ntsej muag kawg yog tiaj tus thiab zoo nkauj. Ob peb yam tseem ceeb uas cuam tshuam rau qhov cuam tshuam ntawm kev kaw cua sov yog qhov kub, lub sijhawm kaw cua sov, lub core dov thiab qhov ceev, thiab lwm yam.

Feem ntau hais lus, qhov kub ntawm kev kaw cua sov hloov pauv nrog rau qhov tuab ntawm zaj duab xis thiab cov khoom siv. Yog tias qhov tuab ntawm zaj duab xis ntawm tib cov khoom siv yog 3μm, qhov kub ntawm kev kaw cua sov yog nyob rau hauv qhov ntau ntawm 280 ℃ thiab 350 ℃, thaum qhov tuab ntawm zaj duab xis yog 5.4 μm, qhov kub ntawm kev kaw cua sov yuav tsum tau kho rau qhov ntau ntawm 300cc thiab 380cc. Qhov tob ntawm kev kaw cua sov yog ncaj qha cuam tshuam nrog lub sijhawm kaw cua sov, qib crimping, qhov kub ntawm hlau soldering, thiab lwm yam. Kev tswj hwm qhov tob ntawm kev kaw cua sov kuj tseem ceeb heev rau seb puas tuaj yeem tsim cov capacitor cores tsim nyog.

5. Xaus Lus

Los ntawm kev tshawb fawb thiab kev txhim kho hauv xyoo tas los no, ntau lub tuam txhab tsim khoom siv hauv tsev tau tsim cov khoom siv winding capacitor zaj duab xis. Ntau ntawm lawv zoo dua li cov khoom zoo sib xws hauv tsev thiab txawv teb chaws hauv cov nqe lus ntawm cov khoom siv tuab, qhov ceev winding, kev ua haujlwm demetallization thiab cov khoom winding, thiab muaj qib thev naus laus zis thoob ntiaj teb. Nov tsuas yog piav qhia luv luv txog cov thev naus laus zis tseem ceeb ntawm cov txheej txheem winding capacitor zaj duab xis, thiab peb vam tias nrog kev nce qib tas mus li ntawm cov thev naus laus zis ntsig txog cov txheej txheem tsim cov capacitor zaj duab xis hauv tsev, peb tuaj yeem tsav tsheb kev txhim kho ntawm kev lag luam tsim cov khoom siv capacitor zaj duab xis hauv Suav teb.

Lub sijhawm tshaj tawm: Lub Peb Hlis-15-2022