Lub lim tiam ua ntej, peb tau qhia txog cov txheej txheem winding ntawm zaj duab xis capacitors, thiab lub lim tiam no kuv xav tham txog cov thev naus laus zis tseem ceeb ntawm zaj duab xis capacitors.

1. Kev tswj kev nro tas li

Vim qhov kev xav tau ntawm kev ua haujlwm tau zoo, winding feem ntau yog nyob ntawm qhov siab dua feem ntau hauv ob peb microns.Thiab yuav ua li cas kom ntseeg tau qhov nro tas li ntawm cov khoom siv zaj duab xis hauv cov txheej txheem high-speed winding yog qhov tseem ceeb tshwj xeeb.Nyob rau hauv tus txheej txheem tsim peb tsis tsuas yog yuav tsum xav txog qhov tseeb ntawm cov neeg kho tshuab qauv, tab sis kuj muaj ib tug zoo meej nro tswj system.

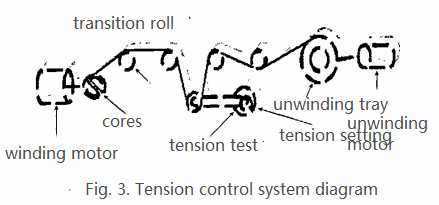

Lub kaw lus tswj feem ntau muaj ntau qhov chaw: nro adjusting mechanism, nro nrhiav sensor, nro kho lub cev muaj zog, hloov mechanism, thiab lwm yam.

Zaj duab xis capacitors yuav tsum muaj qee qhov kev nruj tom qab winding, thiab txoj kev winding thaum ntxov yog siv lub caij nplooj ntoos hlav li damping los tswj lub winding nro.Txoj kev no yuav ua rau tsis sib xws thaum lub tshuab winding nrawm nrawm, qeeb thiab nres thaum lub caij winding, uas yuav ua rau lub capacitor yooj yim los yog deformed, thiab qhov poob ntawm lub capacitor kuj loj.Nyob rau hauv cov txheej txheem winding, ib qho kev nruj yuav tsum tau khaws cia, thiab cov qauv yog raws li nram no.

F=K×B×H

Hauv cov qauv no:F-Tesion

K-Tesion coefficient

B- Zaj duab xis dav (mm)

H-Zaj duab xis thickness (μm)

Piv txwv li, qhov nro ntawm zaj duab xis dav = 9 hli thiab zaj duab xis thickness = 4.8μm.Luas = 1.2 x 9 x 4.8 = 0.5 (N)

Los ntawm kev sib npaug (1), qhov ntau ntawm kev nro tuaj yeem muab tau.Lub eddy caij nplooj ntoos hlav nrog zoo linearity yog xaiv raws li qhov nro qhov chaw, thaum lub tsis sib cuag magnetic induction potentiometer yog siv raws li qhov nro tawm tswv yim nrhiav kom tau cov zis torque thiab kev taw qhia ntawm lub unwinding DC servo lub cev muaj zog thaum lub sij hawm winding lub cev muaj zog, thiaj li hais tias qhov nro. yog tas mus li thoob plaws hauv cov txheej txheem winding.

2. Winding tswj tshuab

Lub peev xwm ntawm capacitor cores yog ze ze rau cov xov tooj ntawm cov lem ntawm winding, yog li precisioin tswj ntawm capacitor cores dhau los ua ib qho tseem ceeb thev naus laus zis.Lub winding ntawm capacitor core feem ntau ua tiav ntawm kev kub ceev.Txij li thaum tus naj npawb ntawm winding tig ncaj qha cuam tshuam rau lub peev xwm tus nqi, kev tswj tus naj npawb ntawm winding lem thiab suav yuav tsum muaj qhov raug siab, uas feem ntau yog ua tiav los ntawm kev siv lub ntsuas kub ceev los yog lub sensor nrog qhov ntsuas qhov tseeb.Tsis tas li ntawd, vim tias qhov yuav tsum tau ua kom cov khoom siv nro hloov me ntsis raws li qhov ua tau thaum lub sij hawm winding ( txwv tsis pub cov khoom yuav inevitably jitter, cuam tshuam lub peev xwm raug), lub winding yuav tsum tau siv ib tug zoo tswj technology.

Segmented ceev tswj thiab tsim nyog acceleration / deceleration thiab variable speed processing yog ib txoj kev zoo dua: sib txawv winding speeds yog siv rau txawv winding lub sij hawm;Thaum lub sijhawm hloov pauv ceev, acceleration thiab deceleration yog siv nrog qhov tsim nyog sib txawv ntawm qhov nrawm kom tshem tawm jitter, thiab lwm yam.

3. Demetallization Technology

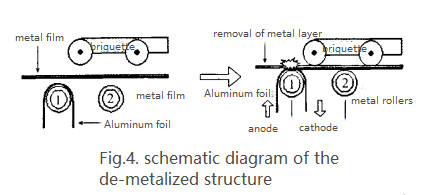

Ntau txheej ntawm cov khoom raug mob rau sab saum toj ntawm ib leeg thiab xav tau kev kho cua sov sealing ntawm sab nrauv thiab qhov sib txuas.Yog tias tsis muaj cov khoom siv yas yeeb yaj kiab, cov yeeb yaj kiab hlau uas twb muaj lawm yog siv thiab nws cov yeeb yaj kiab hlau yog siv thiab nws cov hlau plating raug tshem tawm los ntawm cov txheej txheem de-metalization kom tau cov yas zaj duab xis ua ntej lub sealing txheej.

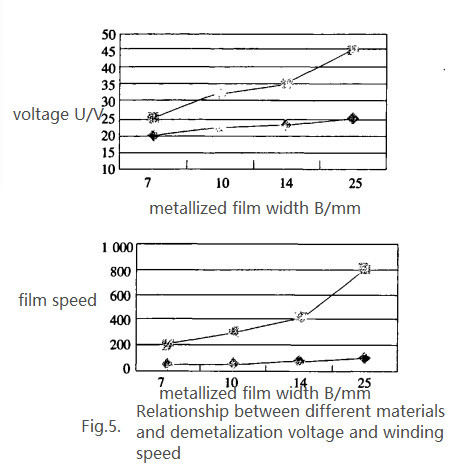

Cov cuab yeej no tuaj yeem txuag cov nqi ntawm cov khoom siv thiab tib lub sijhawm txo qis sab nraud ntawm lub capacitor core (nyob rau hauv rooj plaub ntawm qhov sib npaug ntawm cov tub ntxhais).Ntxiv rau, los ntawm kev siv thev naus laus zis demetalization, txheej txheej hlau ntawm ib txheej (los yog ob txheej) ntawm cov yeeb yaj kiab hlau tuaj yeem raug tshem tawm ua ntej ntawm cov tub ntxhais interface, yog li zam qhov tshwm sim ntawm qhov tawg luv luv, uas tuaj yeem txhim kho cov txiaj ntsig zoo. ntawm coiled cores.Los ntawm Figure.5, nws tuaj yeem xaus lus tias kom ua tiav cov txiaj ntsig kev tshem tawm tib yam.Qhov hluav taws xob tshem tawm yog tsim los kho tau los ntawm 0V txog 35V.Qhov ceev yuav tsum raug txo mus rau ntawm 200r / min thiab 800 r / min rau demetalization tom qab kev kub ceev winding.Qhov sib txawv voltage thiab ceev tuaj yeem teeb tsa rau cov khoom sib txawv.

4. Thaum tshav kub kub sealing tshuab

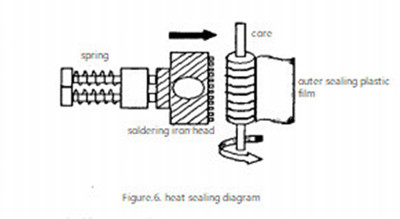

Thaum tshav kub kub sealing yog ib qho ntawm cov thev naus laus zis tseem ceeb uas cuam tshuam rau kev tsim nyog ntawm lub qhov txhab capacitor cores.Thaum tshav kub kub sealing yog siv high kub soldering hlau rau crimp thiab khi cov yas zaj duab xis ntawm lub interface ntawm coiled capacitor core raws li qhia nyob rau hauv Figure.6.Yog li ntawd cov tub ntxhais yuav tsis tau xoob dov, nws yuav tsum tau muab khi ruaj khov thiab lub ntsej muag kawg yog tiaj tus thiab zoo nkauj.Ob peb lub ntsiab tseem ceeb uas cuam tshuam rau lub tshav kub sealing nyhuv yog temperture, tshav kub sealing lub sij hawm, core yob thiab ceev, thiab lwm yam.

Feem ntau hais lus, qhov kub ntawm cov cua sov sealing hloov nrog lub thickness ntawm zaj duab xis thiab cov khoom.Yog hais tias lub thickness ntawm cov zaj duab xis ntawm tib yam khoom yog 3μm, qhov kub thiab txias sealing yog nyob rau hauv ntau yam ntawm 280 ℃ thiab 350 ℃, thaum lub thickness ntawm cov zaj duab xis yog 5.4μm, qhov kub ntawm tshav kub sealing yuav tsum tau kho nyob rau hauv ntau yam. 300 hli thiab 380 hli.Qhov tob ntawm cov cua sov sealing yog ncaj qha ntsig txog lub sij hawm thaum tshav kub kub sealing, crimping degree, soldering hlau kub, thiab lwm yam. Lub mastering ntawm tshav kub sealing qhov tob kuj tseem ceeb tshwj xeeb tshaj yog rau seb puas tsim nyog capacitor cores yuav ua tau.

5. Cov lus xaus

Los ntawm kev tshawb fawb thiab kev loj hlob nyob rau hauv xyoo tas los no, ntau cov khoom siv hauv tsev tau tsim cov khoom siv capacitor winding.Ntau yam ntawm lawv zoo dua li cov khoom qub hauv tsev thiab txawv teb chaws nyob rau hauv cov nqe lus ntawm cov khoom thickness, winding ceev, demetallization muaj nuj nqi thiab winding khoom ntau yam, thiab muaj thoob ntiaj teb advanced technology.Ntawm no tsuas yog cov lus piav qhia luv luv ntawm cov thev naus laus zis tseem ceeb ntawm zaj duab xis capacitor winding technics, thiab peb cia siab tias nrog kev nce qib ntawm cov thev naus laus zis cuam tshuam nrog cov txheej txheem kev tsim cov yeeb yaj kiab hauv tsev, peb tuaj yeem tsav lub zog loj hlob ntawm cov yeeb yaj kiab capacitor tsim khoom lag luam hauv Suav teb. .

Post lub sij hawm: Mar-15-2022